Techflow Enterprises Pvt Ltd is competently one of the trusted and major suppliers of products like pulse jet Dust Collector for Rubber Reycycling, Bag House, Dust Recovery System, Air Pollution Control Device, De-Dusting System, Furnace Fume Extraction System, Cassette Type Filter, Online Cleaning Bag Filter, Electrostatic Precipitator, Bag Filter, ESP, Silo Vent Filter, Air Pollution Control Equipment, Centrifugal Fans & Blowers, Flue Gas Emission Control System, Welding Fume Extraction System, Pneumatic Conveying System, Fabric Filter, Offline Cleaning Bag Filter, Reverse Air Cleaned Bag Filter Pulse Jet Dust Collector to different industries domestically and internationally.

We, Techflow Enterprises Pvt Ltd, have been providing essential instruments to numerous industries like Particle Board Manufacturing, Kiln Exhaust, Cement, Hot Gases and Fumes, Mining and Minerals, Boilers Flue Gas, Coal Handling, Air Pollution Control Systems, Foundry & Steel, Solid Drying, Glass, Wood-Working & Laminates, and more other industries.

Discover more| Dust Collector for Rubber Recycling Applications |

|---|

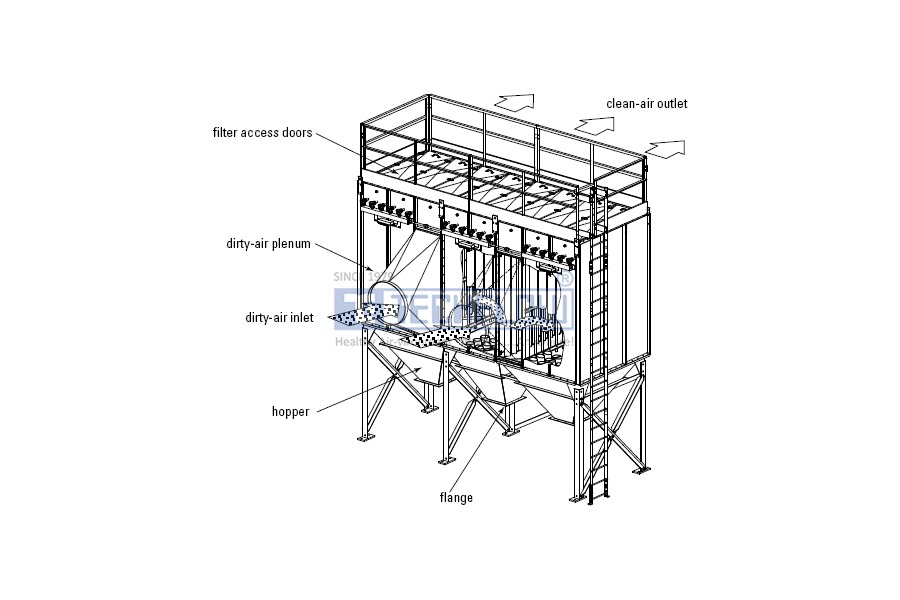

In Pulse Jet Dust Collector for Rubber Reycycling, the spoiled air rushes through the cartridges and retains the dust molecule, ensuring that only clean and contamination-free air remains in the environment. The Cartridge type Pulse Jet Dust Collector for Rubber Reycycling has the benefits of compact design and acquisition of low space. This is the major reason why these systems are widely used in Rubber Recycling. Techflow presents a vast combination of Pulse Jet Dust Collector for Rubber Recycling, having a range between 1000 CuM/Hr to 1,00,000 CuM/Hr. These Cartridge Filters are functional with extra spares and alternatives like a technology of surface filtration, discharge device, and a variety of fabrics suited for various applications. |

TECHNOFLOW constructs and supplies a hugely efficient pollution control system. These systems are known many names nationally and internationally, we can take, Pulse jet Dust Collector for Rubber Recycling, bag filter for boiler, De-dusting system, Pulse jet bag filter, Baghouse, Bag Filter, and ESP for a boiler.

|

1. Online Cleaned Pulse Jet Dust Collector for Rubber Recycling

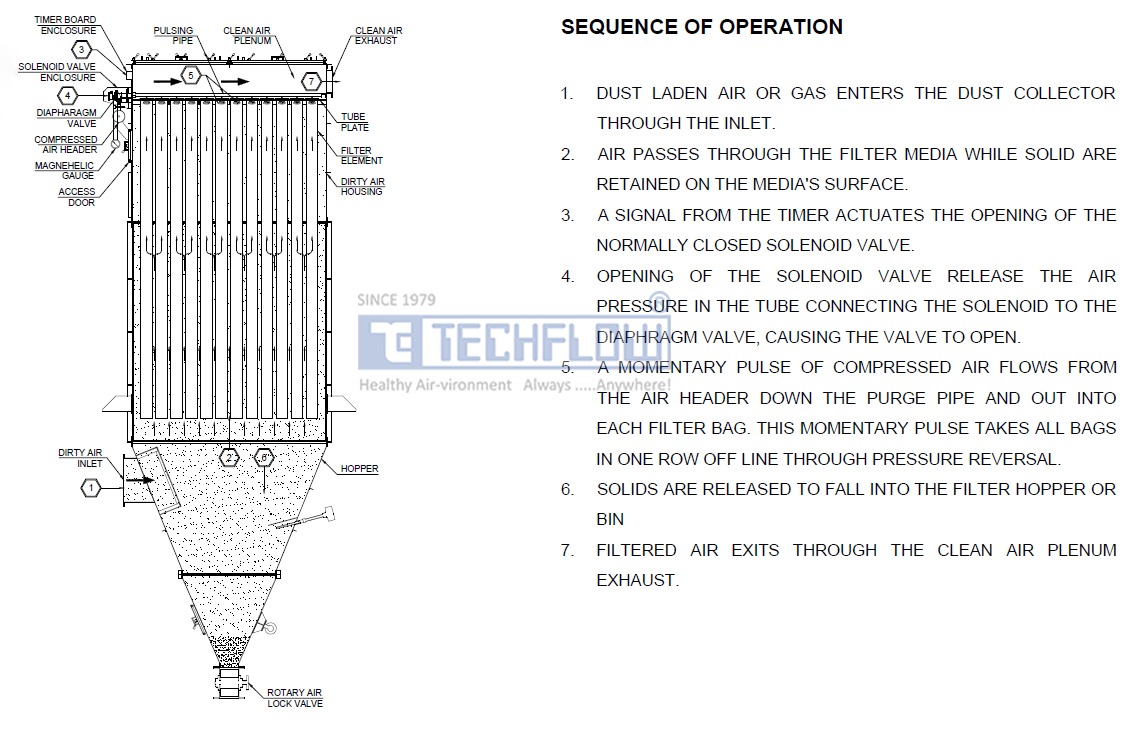

The air that is filled with dust enters the hopper where the heavy molecule falls out of the air stream. The heavier particles are caught in the air and rise into the filter bags as a result. As the cleaned air is drained through the collector, it passes through the filter bags, collecting dust particles on their exterior side surfaces. Through blowpipes and pulses, the pressured air jets moved through the venturies at precise intervals. This includes a secondary air flow that is strong and temporarily switches through the bags. As a result, an internal shock wave is created, which causes the bag to compress and expand outward as the shock propagates down its length. The procedure allows dust to be released from the inverted airflow on the bag's surface, which sinks into a collection known as a hopper. This technique switches the airflow across a row of bags, but only for a brief moment. This then creates a continuous airflow across the dust collector. The Cleansing Operation is simply adjusted and managed by a Solid State timer. A differential pressure gauge enables and regulates the timer's flawless regulation. To lessen the compressed air consumption in the process, the pulse gaps and durations can be precisely and simply adjusted at the timer.

2. Off line Cleaned Pulse Jet Dust Collector for Rubber Recycling

It's also feasible to divide the Pulse-Jet baghouses. In this instance, the isolation/poppet valves located in the clean air plenum regulate the passage of the impure air into the compartments. One of two options is to install a single pulse valve in each compartment, which pressurises the group of bags, or to install individual pulsing valves, which direct the immediate pulsing air into the blowpipes outside the bag rows in the compartment. During the cleaning procedure, the isolation damper closest to the compartment blocks the airflow. Through the pulse valve's entrance, air is blasted into the bags for around two seconds as part of the cleaning process. The compartment remains offline throughout the pulsing process. The duration of that can be increased or decreased depending on the situation. Upon the automatic closure of the isolation/poppet, the compartment is returned to the stream. The alternative compartments are cleaned one after the other using a technique known as "off-line cleaning" up until and unless all of the bags in the baghouse are cleaned. While the baghouse constantly achieves much lower emission levels, It lets complete bag cleaning as it is oftentimes usees on fabric filters installed on lower bulk density product/dust.